📑 Table of Contents

The chronograph, as one of the more popular watchmaking complications, has become somewhat devalued in recent time, so it a relief to see that the Geneva watch manufacturer, Patek Philippe, has decided to demonstrate how a proper chronograph should be made.

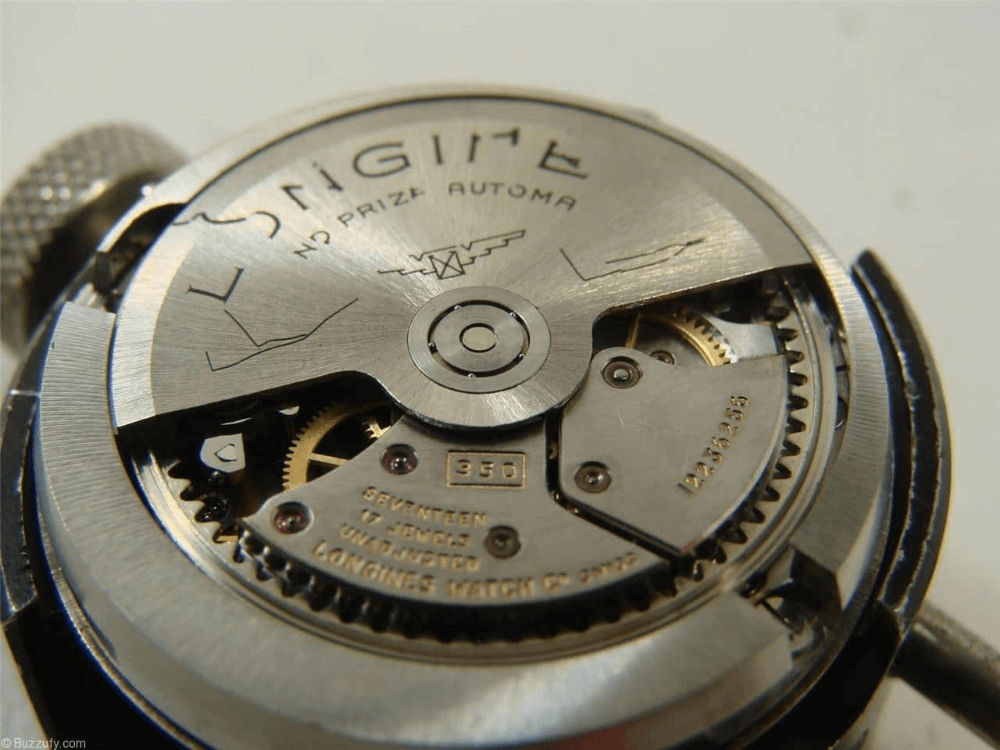

The manually wound CH 29-535 PS chronograph caliber follows the old conventions – the horizontal engagement of the movement with the chronograph, a column-wheel to direct the brake, clutch and reset levers, and a minutes counter that jumps smartly to the next minute.

However it’s the detail that makes the difference, and this movement is a good example of a traditional approach to watchmaking that few brands uphold today.

Eliminating false starts

The horizontal clutch is simple, it keeps the movement slim, but it has a major drawback. When the two wheels come into contact, tooth might butt against tooth, forcing the central chronograph wheel to turn slightly to allow the teeth of the clutch wheel to mesh. This causes an almost imperceptible jump of the chronograph seconds – just a fraction of a second forwards or back – when the chronograph is started.

This of course won’t do. The firm has therefore applied its finest mathematical and engineering minds to the design of new tooth profiles that greatly reduce the intolerable possibilities of a false start of the chronograph seconds.

Furthermore, the new tooth profiles improve the tranmission efficiency of the chronograph when engaged.

Synchronizing clutch and brake

When you start a chronograph, the brake that blocks the seconds hand must be released the moment the clutch throws the chronograph into gear. Conversely the brake must be applied as the clutch disengages, or the chronograph hand will be all over the place.

Synchronizing the clutch and the brake has until now required the fine adjustment of their separate levers, each controlled by the column-wheel.

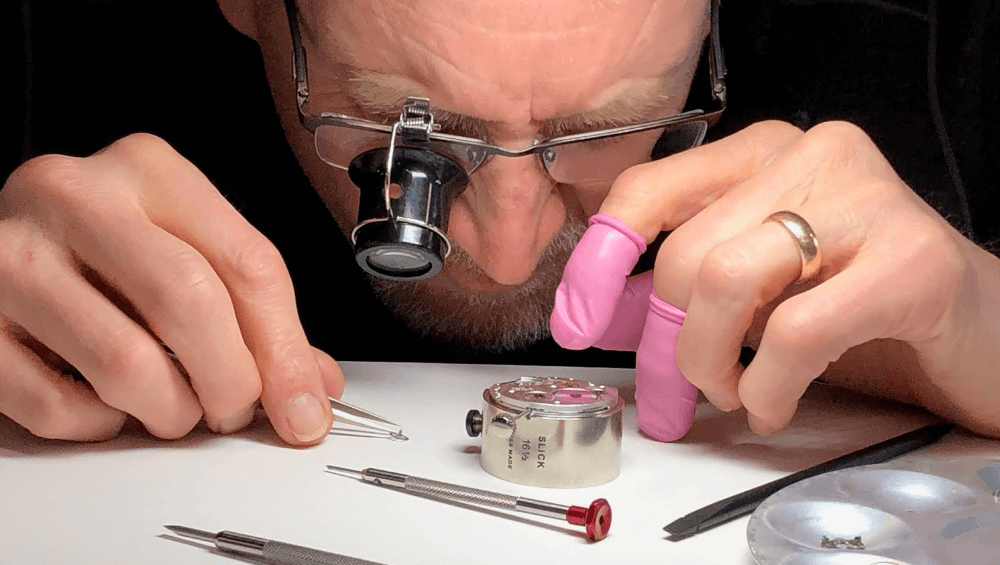

In this chronograph, the brake lever is operated by an arm of the clutch lever instead of directly by the column wheel. An eccentric screw on the brake lever (shown here held against the polished arm of the clutch lever) allows the watchmaker to adjust the travel and timing of the brake in relation to the clutch, ensuring that they both operate in synchronization.

It is amazing that no watchmaker has come up with this simple solution before, and that Patek Philippe has been able to claim a patent for it.

The eccentric cap

It is one of the eccentricities of Patek Philippe to hide its column-wheel under a cap; lesser brands expose their column-wheels just to show they have this widely considered attribute of the better class of chronograph.

The now defunct purpose of this cap was to prevent the column-wheel levers from popping out if the watch is joited.

Rather than remove the cap and commit the unspeakable vulgarity of exposing the column-wheel, the constructors have found a new use for it. The cap serves to adjust the depth at which the chronograph wheels mesh together. If they engage too toghtly, the movement grips; to loosely and the chronograph hand shudders.

Past chronographs have used an eccentric screw placed awkwardly near the middle of the movement to adjust the depth. Instead of a screw, the column-wheel cap on this model is made eccentric by a tenth of a millimeter, controlling the depthing at the far end of the clutch lever. The watchmaker need only rotate the eccentric cap to adjust the depth.

Flicking minutes

No disceming collector will consider any chronograph whose minutes counter moves sloppily from one minute to the next, either progressively or in a little rush during the last few seconds.

In the proper chronograph, the minutes counter jumps smartly and instantly to the next minute as soon as the chronograph seconds hand reaches 60 on the dial.

Usually this is done by a sprung lever climbing up the spiral slope of a snail cam rotating with the chronograph seconds. At the end of a minute, it crashes down the cliff at the end of the slope, bringing the minutes counter abruptly forward one minute.

However, this system puts an unacceptable drag on the movement when the chronograph is going. To mitigate this, the constructors of the CH29-535 PS have adopted a much wider, lighter and gently sloping one-coil spiral, part of which can be seen through the aperture in the chronograph wheel. On it rides a delicate and rapid-action spring, rather than a heavy fever, which advances the minutes counter instantaneously when it flicks off the end of the spiral.

Self adjusting hammers

The chronograph hands return to zero when hammers fall on their heart pieces – specially shaped eccentric cams designed to swing the hands round to zero when pused by the hammers. Here you can see the hammers, like the forelegs of a horse, resting on the seconds heart cam (left) and the minutes heart (right).

In your ordinary chronograph, the hammer levers are fixed in relation to one another and it is very tricky get them both to sit firmly and equally on their respective heart cams in the zero position.

Here the minutes hammer on the right is independently sprung and pivots on the seconds hammer (left) at the screw. This articulation allows each sprung hammer to find its own best position on its heart cam independently from its twin, and to bring its corresponding chronograph hand precisely to zero. I hope Patek Philippe showers with gold the genuis who invented this beautifully simple, self-adjustung device. Furthermore it is pivoted between jewels !

The 13-ligne caliber CH 29-535 PS first appeared in a ladies’ chronograph in November 2009.