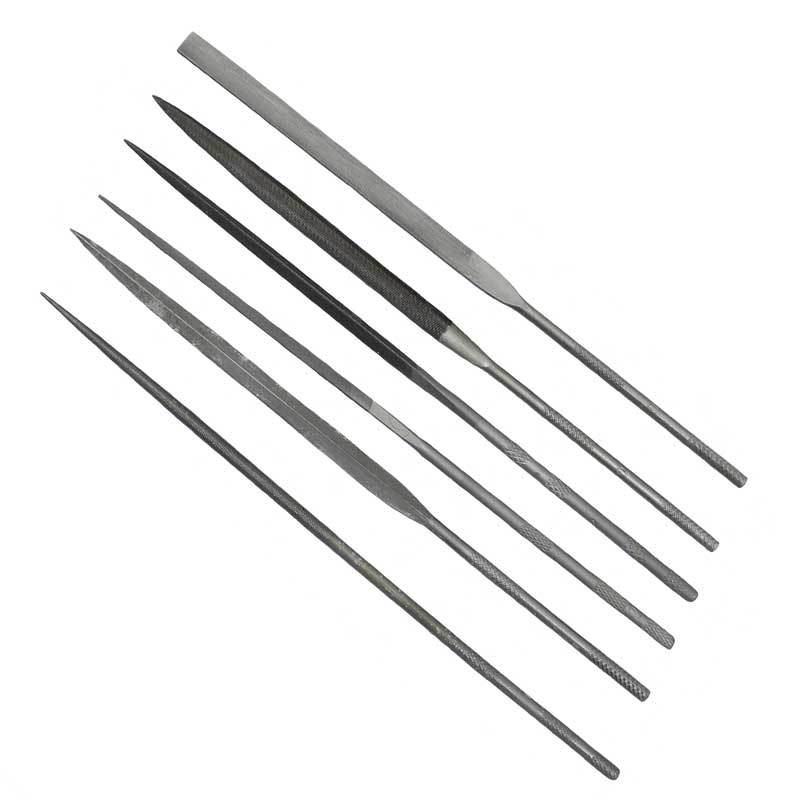

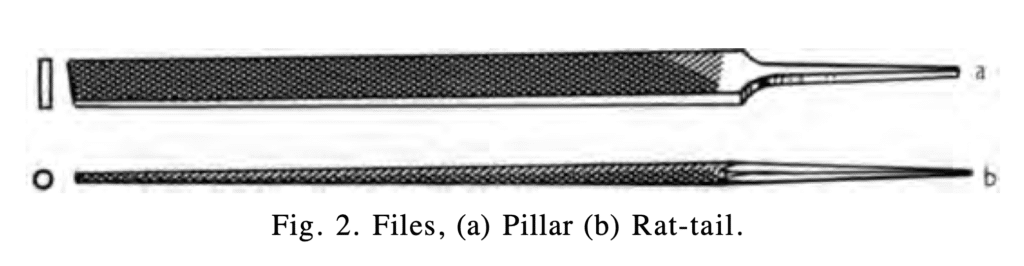

The two most useful types of file for watch and clock repairing are pillar files and rat-tail files (Fig. 2). Useful sizes are 4 in. and 6 in. in coarse, medium and fine cuts.

Files are cutting tools and must be treated as such. The teeth are shaped like those of a saw and consequently cut in one direction only.

Soft metals such as brass need new files but steels can be cut better with a part worn file where the tips of the teeth have been worn down. It follows then that new files commence their life by being used for brass and are then passed over for use on steels.

It is sometimes more economical to use a double-sided file such as a pillar file, for both metals, in which case the side used for brass is marked by passing a piece of white chalk across the teeth.

It is essential that you are able to file accurately and therefore a little practice may prove worth while.

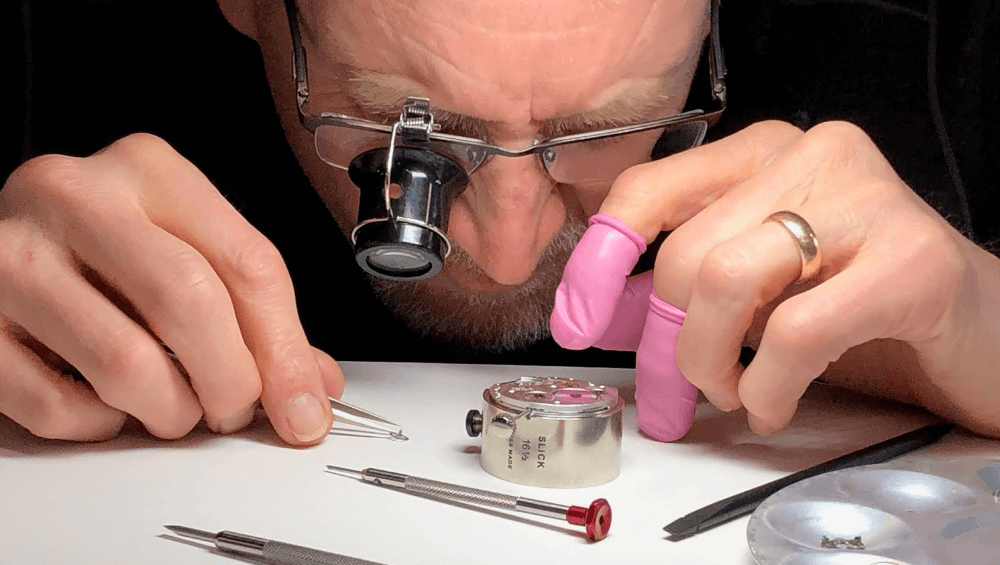

Place a piece of brass rod horizontally in the vice. Hold the pillar file by the handle in the right hand. Place the file on the brass and place the forefinger and thumb of the left hand on the end of the file.

A forward stroke is now made with just sufficient downward pressure for the file teeth to cut the metal.

A flat surface can best be obtained by keeping the file hori- zontal. To do this the stroke is made with a light downward pressure on the file handle and a heavier downward pressure on the file tip.

As the centre of the file nears the brass, so the two pressures are adjusted until, when the file is equidistant over the brass the two pressures are the same.

As the stroke continues, the two downward pressures are pro- gressively reversed until, when the file has reached the end of its stroke, the heavier downward pressure is being made on the handle and the lighter downward pressure on the tip.

A little practice and it will be found that the knack of maintain- ing these varying pressures will not be difficult.

Pillar files usually have both edges smooth thus enabling one face of a step to be filed without removing metal from the adjacent face.

Quite frequently taper pins will have to be made by filing; this is known as ‘pin-filing’.

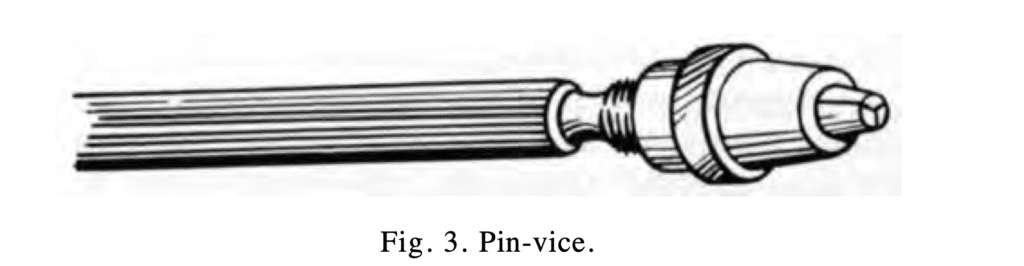

A small block of fibre or hard wood is needed having in one face a number of grooves of varying depths. The block is placed in the vice with the grooves uppermost. A piece of selected brass rod or wire is placed in the jaws of the pin-vice (Fig. 3), the protruding length dependent on the length of the pin required.

The wire is laid in one of the grooves and held at a slight downward angle. The groove selected is that which allows the wire to just stand proud of the surface of the block.

A fine pillar file is selected and a light forward stroke is made. The right hand can control the file better if the forefinger is straight and its tip resting on the side of the file. At the same time the pin-vice is rotated between the forefinger and thumb of the left hand causing the wire to revolve against the direction of the file.

When the stroke is completed, the file is drawn back, lightly resting on the wire to keep the wire in the groove, and the pin-vice is rotated in the opposite direction in readiness for the next stroke.

A little practice and synchronization of movement will be achieved.