The very private Swiss watch giant opens the doors of its new Geneva facility.

Rolex has always had a Garbo-like sense of privacy. With no very good reason to court the media, or even allow them through its doors, it chugs happily along, selling its roughly three-quarters of a million watches a year, which bring in some 2 billion Swiss francs (this is an estimate; the company, needless to say, does not reveal sales figures). As the world’s biggest luxury watch brand, with a sterling image that never fades, Rolex needs publicity like Garbo needed more fans.

So recently, when Rolex invited us to visit its facilities in Geneva, to actually go inside them and see real Rolex employees making real Rolex watches, we didn’t think twice.

Rolex’s Geneva facilities are in the final stages of a massive, eight-year-long construction and renovation project. Its aim is to bring together the many manufacturing operations, some 19 in all, that were once spread out in and around Geneva. In the late 1990s, when a wave of consolidation swept over the watch industry, Rolex began to buy up many of its suppliers in order to gain greater control of them, creating what the company refers to as “the Rolex Group.”

As Patrick Heiniger, managing director and CEO, explains in a brochure about the Geneva facilities, “At the start of the 21st century, we made a strategic decision to ensure our autonomy and maintain control over the essential components of our watches. We integrated our Swiss suppliers into the Group, and consolidated our Geneva activities at three new sites in buildings that exemplify state-of-the-art technology.”

These suppliers included the bracelet maker Gay Frères, the case maker Genex, the dial manufacturer Beyeler and the winding-crown producer Boninchi. Having brought all of them under the Rolex banner, the company wanted to bring them under the same roof, or rather, three roofs.

The consolidation is the latest chapter in Rolex’s long history in Geneva. The company has been an institution there for nearly a century, almost as much a part of the city’s identity as the famous jet d’eau at the mouth of the Rhône or the lovely waterfront skyline.

Rolex founder Hans Wilsdorf moved Rolex to Geneva in 1919 (the company was born in 1905 in London), and it remained in the city center for more than 40 years. In 1965, Rolex completed construction of new headquarters in an industrial section of Geneva called Acacias, southwest of the city center. Its move there broke with Geneva watchmaking tradition, which held that companies be located on the banks of Lake Geneva.

Now, with just a year or so to go until the last glistening green glass panel is hoisted into position on the refurbished headquarters, Rolex, in an uncharacteristic burst of openness, wants to show off its deluxe new digs.

Life upon the shelves

We start at the spanking new building in Plan-les-Ouates (pronounced “plan lay WHAT”), which was completed last October. This district, on the outskirts of Geneva, has recently become a luxury-watch stronghold. Patek Philippe, Vacheron Constantin, Piaget, and Frédérique Constant have all built new production facilities there, turning the flat, featureless expanse into a showcase of eye-catching, ultra-modern industrial architecture. Rolex’s building is the most imposing of all; it is huge (it covers nearly 26,000 square meters of space, roughly the size of five football fields), jetblack, and forbidding.

Inside, we see a short movie presenting facts and figures about the new building. It’s 11 stories high, we’re told, with five of them underground, and composed of three parallel, rectangular units, connected by a central corridor. It has 157,000 square meters of floor space and houses 1,700 machines. Deliveries are made via a 10-meter-wide covered road that runs through the building. The roof is covered with gardens and is used as a relaxation area by the 1,500 people who work in the facility.

The glass that completely covers the building shields the work within from prying eyes. Those lucky enough to penetrate that armor are in for a treat, the film’s narrator suggests. “The black glass facades conceal a surprising world,” he says.

He’s right, as we discover from the very first stop on the tour. It’s the components storage room (the prosaic name doesn’t do it justice, as we soon find out), on the second underground floor. To get there, we pass through an ultra-secure entryway equipped with a retina-scanning system, meant to foil thieves with designs on the treasure within.

We stand on a walkway, behind a floor-to-ceiling pane of glass, and look upward and downward at layer upon layer of storage shelves: four stories’ worth of them, holding 30,000 separate compartments. (There are an additional 30,000 compartments in a second storage room, a precaution in case disaster strikes the first one.)

The vast expanse of shelves is itself impressive, but the real spectacle is the computer-directed conveyors that pick up the components from the bins and deliver them to work stations throughout the building. There are countless of these automated gofers zipping along aluminum rails, stopping, snatching the parts from the compartments, and zipping away again. Four kilometers of these rails snake through the facility; the system extends to the building’s farthest reaches. The average wait for components, once they’ve been ordered from a workstation by means of a few mouse clicks, is eight minutes.

We gaze for quite a while, transfixed by the speeding conveyors, whose loud, constant whirring makes it difficult to hear anything below a shout. We laugh like kids in a funhouse when once in a while a conveyor comes zooming toward us as if to crash through the glass pane, then stops short at its destination a few feet from our faces.

The Rolex production manager leading the tour tells us the system is working above Rolex’s initial expectations, and is 98% reliable. Then he herds us away, which, given our fascinated dailly-dallying, is like herding cats.

Gold standards

Where do these components – cases, bracelet links, tiny bracelet fixings, clasps, and myriad other bits – come from? To find out, we take the elevator up to the ground floor. We’re on our way to the foundry to see, as the movie describes it, “the first step in the creation of a Rolex.”

The company mixes its own gold, enabling it to both create its own alloys, like a special blend of pink gold it recently developed (the alloy doesn’t lose its pink tint, the way some other pink-gold alloys eventually do, Rolex says), and to control the gold’s quality. Rolex is the biggest user of gold in Switzerland and the only watch company that does its own alloying.

We see the end product in a so-called “gold pour,” in which half a gallon of fiery molten gold streams from a crucible into a pan. After it cools, the metal is stamped into cases or casebacks or drawn through a series of dies to form gold wire of the right shape to make the various Rolex bracelets: the Oyster, the President, etc.

Because Rolex uses so much gold, it’s able to employ machines normally used for steel or aluminum, which are larger than standard gold-processing machines and hence more precise. It’s a good thing: we’re told that the tolerance for bracelet-component parts is 2/100 of a millimeter (each bracelet has about 200 parts), and that’s why a Rolex bracelet will last 30 to 40 years without needing repair.

Steel parts are made in the same department. Rolex uses an alloy known as 904L (it’s the only watch company to do so, it says) that it buys from outside suppliers. The steel resists corrosion extremely well and is also very tough, so that it’s durable, but quite difficult to machine.

After the parts are fabricated, they’re polished. A robot, enclosed in a glass cubicle, handles the initial polishing. We watch it (him? it’s wearing a baby-blue dust cover that cloaks its oddly misshapen body), mesmerized by its jerky but somehow lifelike movements, as it “holds” a watchcase against a polishing machine. It’s nightmarish and funny at the same time, like the creatures in the bar scene in “Star Wars.”

The robot is a high-maintenance employee: we’re told it needs to be recalibrated after every 10 cases it polishes to keep it working with the required precision. But it clearly earns its keep: “With a little help from the robots, you can make a very good product,” the Rolex manager cheerfully points out, glancing at his electronic colleague.

When the robot is finished, the case is passed along to humans for fine polishing. Only real hands and eyes can detect tiny imperfections that might remain on the case’s surface, we’re told.

Robo jock

Our next stop is the laboratory, where scientists, engineers and technicians (there are 20-plus PhD’s employed there), work on quality control, research and development and general trouble-shooting, like fixing a glitch on the production line or diagnosing the cause of a difficult-to-open bracelet clasp. “You can see there are people at the center of Rolex, not machines,” the Rolex manager tells us. Simple tasks have been reassigned to robots, he explains, but people still do the complicated ones.

These jobs include making sure the raw materials are sufficiently pure before they’re made into watch parts. This means examining them with a scanning electron microscope. We’re told a story that illustrates how stringent its standards are for raw materials: When Rolex receives bars of steel from its supplier, the company performs different test on them, including a polishing test.

One recent polishing test produced a small scratch, what the technicians call a “comet,” on the surface of the bar. Examining the steel under the electron microscope, the Rolex technicians found a minuscule particle, 8 microns across (1/10 as wide as a hair) in front of the comet. They analyzed it and found that the particle was composed partly of titanium.

They phoned the steel supplier, who told them that the furnace used to alloy the metal had earlier been used to make titanium steel for another customer. The furnace had not been cleaned thoroughly and some traces of titanium remained in it. Hearing this, Rolex rejected the entire load, sending back 10 metric tons of steel.

A few minutes later, in the research and development section of the lab, we learn a new word (new to most of us, that is): tribology, the science of wear and tear. We see another robot, this one dedicated to studying the effects of wear on watch bracelets. The robot has a mannequin-like wrist and hand and wears a Rolex watch. It is performing a sequence of fancy moves with its humanoid hand: twisting it, thrusting it down, turning it sideways, lifting it up, then repeating the series again and again.

The moves, odd as they seem, are modeled on real life. “We put some sensors on a colleague of mine while he was doing different kinds of sports: running, tennis, golf, and everything else,” a research and development manager tells us. “We examined the motions and tried to [duplicate] them with this robot.” The robot allows Rolex to simulate a year’s worth of wear in just one week, and hence discover in a jiffy the advantages of one bracelet design over another.

Behind the bling

We wave good-bye to the robot, which is still frantically gesticulating, and soon pile into a bus headed for the Rolex factory in Chêne-Bourg, a few miles to the east. There, human hands, steady, patient ones, prevail. The first building to be completed in the Rolex remodeling program, in 2000, this facility was once the Genex case factory and is now used for setting gems and making dials.

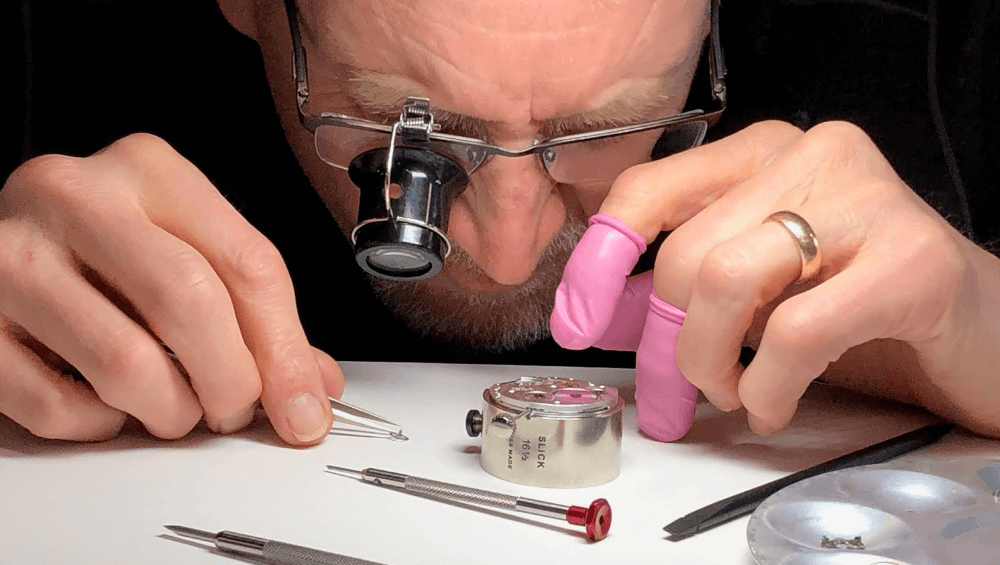

First we see the gem-setting process. In one room, little diamonds are arranged in neat piles, waiting to be placed on bezels, dials and bracelets. Here, their color is checked to make sure it’s the requisite “river” grade (the equivalent of D or E on the Gemological Institute of America’s grading scale, which is widely used in the United States). The diamonds, in round, trapeze, or baguette shapes, are painstakingly set by hand with the aid of a microscope.

In the dial-making department, we see more handwork: printing of the dials and the addition of markers and numerals. Dials are made of brass, gold or platinum. Color is imparted to the dials by a variety of methods: galvanization, physical vapor deposition, or painting. Mother-of-pearl and meteorite dials are made by gluing a thin layer of the decorative material onto a brass substrate.

Putting it together

Another bus ride takes us into Geneva’s city limits to the area called Acacias. We come to our third and final stop, the climax of the tour, in some sense: Rolex worldwide headquarters. This complex, in the final stages of expansion and renovation (it’s scheduled to be finished this year), is where the top Rolex executives, including Patrick Heiniger, have their offices. Rolex-watchers have long regarded the building, covered in glass tinted in imperial Rolex green, as a fortress only a little less impenetrable than the Pentagon.

The facility consists of two side-by-side towers housing offices and administrative departments and, next to them, four industrial buildings. It is in these buildings that Rolex watches are assembled, put through their last quality-control tests, packaged and shipped to markets throughout the world.

Most of the assembly is done by hand at rows of immaculately clean workbenches where employees, most of them women, combine all the pieces made elsewhere (movements from Bienne, cases and bracelets from Plan-les-Ouates, dials from Chêne-Bourg) into the final product.

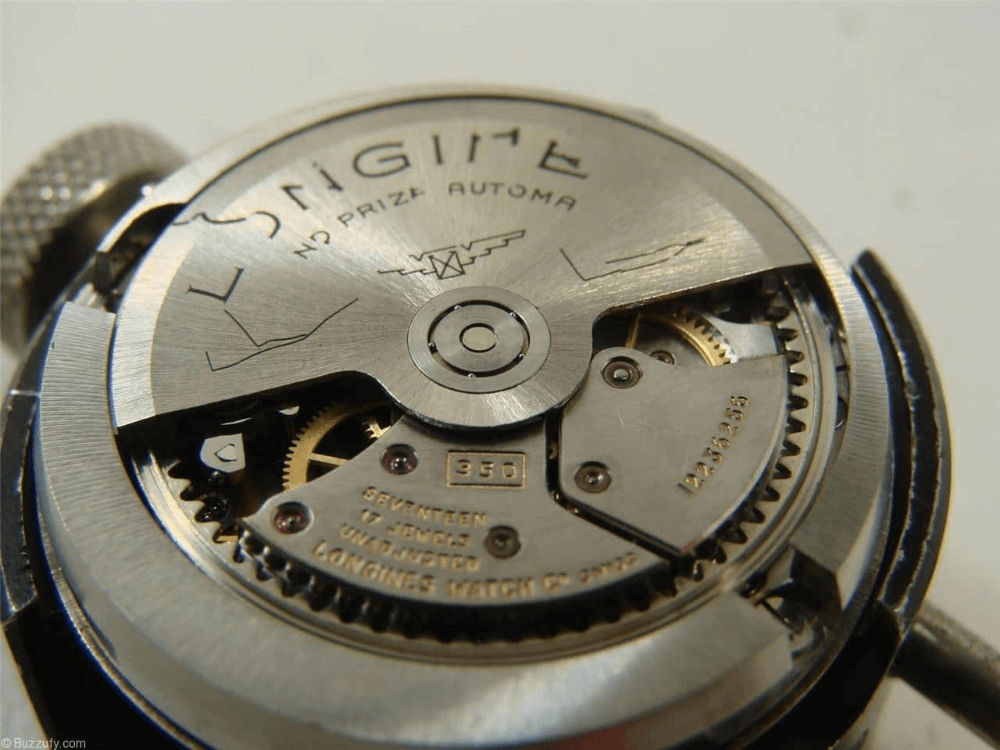

We watch the women, agile-fingered and as steady of touch as micro-surgeons, lifting up tiny gold watch hands (all Rolex watches have gold hands) with an air pump, so they won’t get scratched, and positioning them on the dial. At other workstations, employees are casing the movements and, at still others, placing the winding crowns. One of the final steps is attaching the winding rotor, a task performed with an electric screwdriver programmed to tighten the screws to precisely the right tension.

Throughout it all, the women constantly check and re-check their work. Does the date jump at midnight, as it should? Are the hands precisely superimposed? Is the dial flawless? Does the rotor sound as it should when it turns, or might one screw be a tad too loose? If everything passes muster, the serial numbers of the case and movement, which are engraved by laser, are registered, and the case is closed up.

The watch is still not ready to meet the world. First it must pass a few more tests. Now machines take over. First there’s a water-resistance test using air pressure (the riskier water-resistance test, using water, comes later). Then the watch will be wound automatically, by means of its rotor, to make sure the winding mechanism produces enough energy to keep the movement running. The precision tests come next.

They’re similar to those performed by COSC. (The movements have already been certified by that agency; the purpose of these in-house tests is to make sure the movements still measure up after casing). The dial is photographed once, then again, 24 hours later, and the timing compared to that of a reference clock regulated by an atomic clock.

Then the watch’s precision is measured in each of four different positions. Lastly, the watch is placed in a water tank and tested at a pressure level 10% above what is guaranteed for that particular model. The bracelets are attached, and the watches’ guarantees are placed with their respective watches. The watches are boxed for shipping, and off they go.

And so do we. After a dinner atop one of the towers, hosted by Patrick Heiniger, we leave the headquarters, a bounce in our step. Why? Because we’ve done it, we’ve gotten inside Rolex.