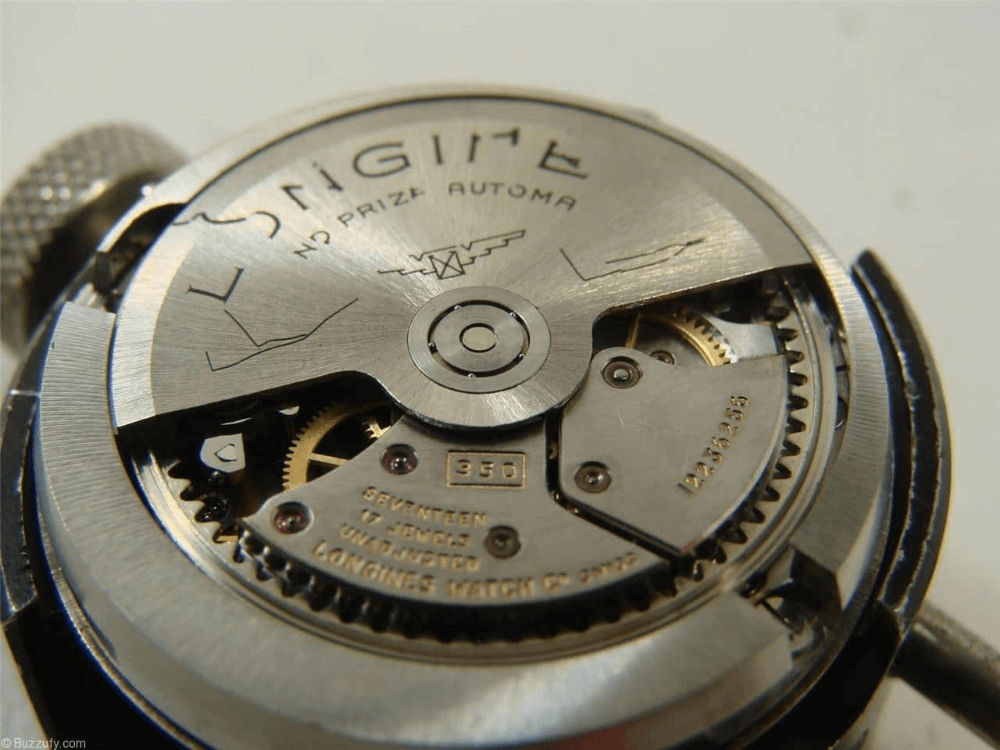

From what does a watch get its power?

From the mainspring. Like any other power-producing mechanism, the mainspring and the barrel in which it is housed are not only of the greatest importance for the good performance of a watch, but also require careful attention while the watch is in the hands of the horologist for cleaning and repairing. It is impossible to get good performance when the mainspring and barrel are imperfect. Even if the train and escapement are in perfect running order, we cannot expect good time keeping when the source of power is not right. Let us consider briefly some of the common defect that are the cause of most barrel and mainspring troubles.

Side and end shake: The barrel must revolve freely on the arbor, but with no excessive side or end shake. The end and side shake of the arbor in its bearings in the plate and bridge must be limited to necessary freedom. Too much side shake will affect the gearing, cause binding, and loss of power.

Barrel arbor upright: Inasmuch as the barrel must turn true, the arbor has to stand upright between the plate and bridge; otherwise, the barrel may rub against the plates or center wheel.

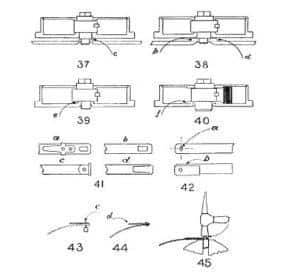

Plate shoulder too large: Fig. 37-C illustrates how the barrel arbor shoulder should rest on the plate-raised seat. Here we see that this seat is smaller in diameter than the shoulder of the barrel arbor. A raised seat larger in diameter than the shoulder, as indicated in Fig. 38-D, will cause the barrel to rest on the plate instead of the arbor. To correct this fault it will be necessary to set the plate in the lathe and turn down the raised shoulder to a diameter smaller than that of the arbor, as shown by the dotted lines in Fig. 38-B.

Mainspring not hooking at center: When a mainspring does not catch properly on the arbor, examine the shoulders inside the barrel and barrel cap. These shoulders should be smaller in diameter than the arbor, as illustrated in Fig. 39-E. Shoulders too large in diameter, as shown in Fig. 40-F, will not permit the spring to wind tight against the arbor. To correct this fault, the shoulder should be turned down until it is smaller, as shown in Fig. 39-E.

How is a mainspring inserted in the barrel?

The mainspring is inserted in the barrel with a mainspring winder. When the mainspring is inserted by hand, it becomes bent out of shape and the acid-charged perspiration of the hands will ruin it.

Which space of the barrel is occupied by the arbor, which by the mainspring?

The mainspring occupies one-third of the diameter of the inside of the barrel, and the arbor another third, while the last third is the space for the mainspring to wind and unwind.

Are all mainspring ends of the same type?

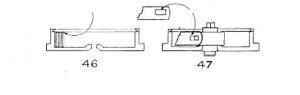

No. There are several types of mainspring ends: ―T‖ ends, pressed-out tongues, loose inserted, riveted and double-brace ends. See Figs. 41-A, B, C, D.

How is a new end riveted?

Select a piece of mainspring of the same size as the spring to which it is to be riveted. Make a center mark as in Fig. 42-A and punch a hole. Using this hole as a guide, mark and punch a hole in the mainspring. Be careful that it is absolutely in the center. If the holes are not in the center, the end will appear as in Fig. 42, causing the mainspring to rub against the barrel cover or on the bottom. With a countersink or large drill smooth out the burs around the holes before riveting. The end that catches on the barrel hook should be shaped as in Fig. 44-D. Polish the parts with a fine file or emery paper. Prepare a rivet to fit the hole snugly, as shown in Fig. 43-C. This rivet should not protrude too much, or it will be difficult to rivet down. Fig. 45 illustrates how to rivet the tongue.

What is a set mainspring?

A set mainspring is one whose coils remain close together when the spring is removed from the barrel.

What is a cupped mainspring?

A mainspring with an upward spiral shape is said to be cupped.

Why do mainsprings break?

Many opinion shave been expressed as to why mainsprings break. However, investigations and tests conducted by mainspring manufacturers point out as the causes of breakages, defects resulting from the many manufacturing processes, that is, the alloying, rolling, cutting, hardening, tempering and polishing the metal until the mainspring is finished.

Why do some mainsprings become kinked?

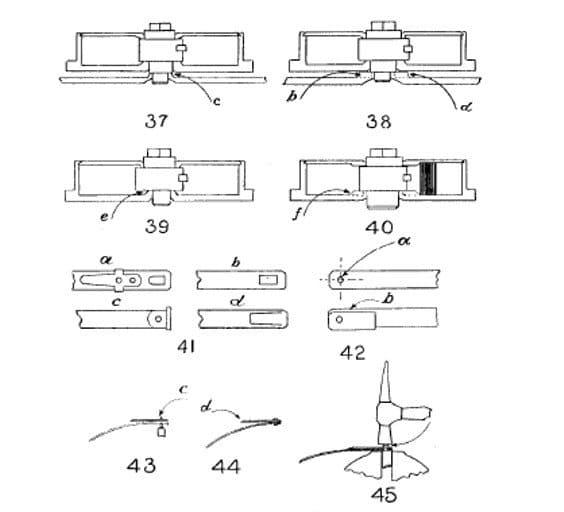

The mainspring coils become kinked when the barrel arbor hook is too large and protrudes too much out of the mainspring hole. This hook must be large enough to hold the spring safely, but not so much as to protrude and cause kinks when the mainspring is tightened around it. Each individual watch requires a mainspring of correct width, length and strength. The width should be such as to reach the barrel cover seat. See Fig. 46. A mainspring that reaches higher than the barrel cover seat is too wide and will rub and bind against the cover of the barrel. This defect will cause the watch to stop or prevent correct timing. A mainspring of correct width may still bind against the barrel cover or bottom if the hole set at the inner end of the spring is not in center. See Fig. 47.