The lathe and its use – part 1

It is now time to give attention to turning in the lathe and lathe work generally, but before doing so it os necessary to discuss the lathe itself.

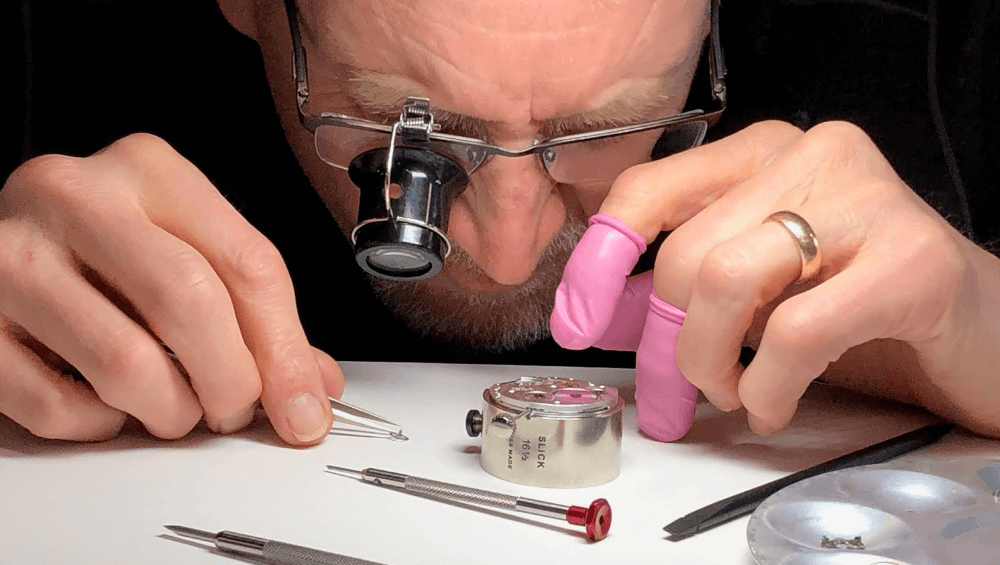

There is little doubt that the lathe is one of the watchmakers’ most valuable tools, it is speedy and efficient, not only speedy in accomplishing the work but, with the various accessories, the fit up of the work is carried out in an expeditious manner. The illustration here is of the simple lathe comprising the bed, headstock, tailstock and T rest; the accessories will be explained as required to do the work in hand.

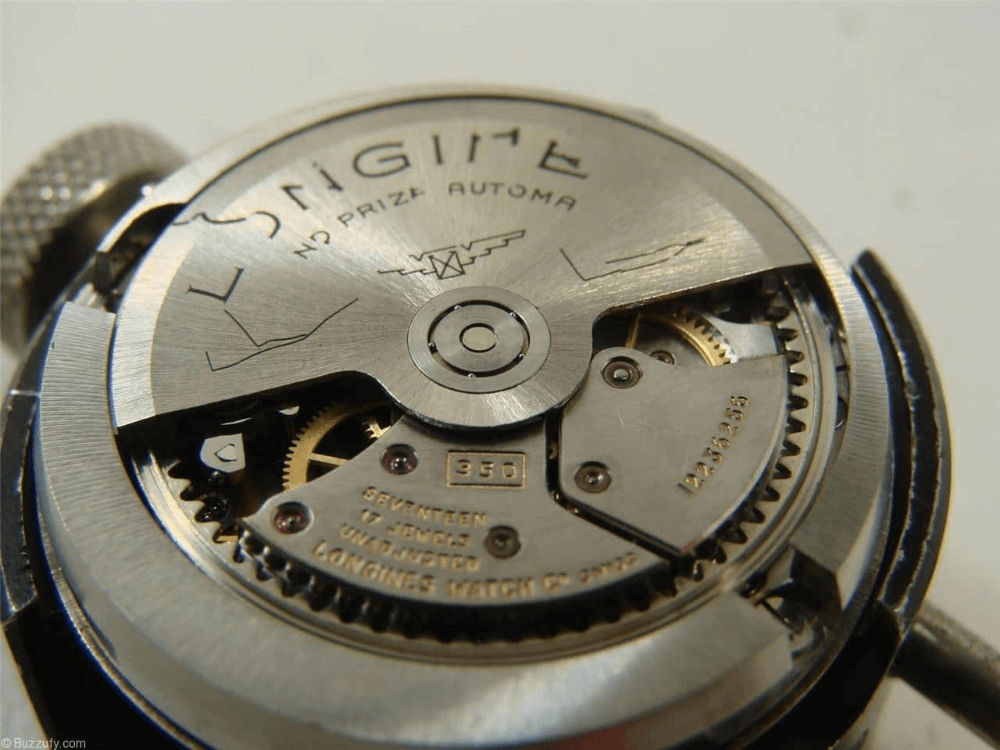

When purchasing a new lathe buy the best possible and one of the popular makes so that accessories are easily come by. Handle the lathe with great care, do not force any of the fixing screws, finger tight is all that is needed in a well-cared-for lathe. This also applies to the draw-in center of the headstock. If, for instance, a split or wire chuck is used, it should not be necessary to force the draw-in center to tighten the work in the chuck, not only will the thread of the chuck and the draw-in centre be saved but also the work will be more accurate. Occasionally, say once in 12 months, take the lathe to pieces and clean all the bearings, see that the oil channels are clean and free from old oil. Reassemble and oil.

When assembling, the headstock should have no endshake at all, but at the same time it must be quite free. To adjust the endshake the grub screws that hold the cone-shaped bearing are loosened, and if it is required to lessen the play between the two fittings of the headstock this cone bearing is pressed inwards. To do this place a piece of woold over one end-the handle of an emery buff answers quite well-and give it a light blow with the clock hammer. If it is necessary to ease the spindle because the cone bearing is too tight, place the handles of two emery buffs over the smaller pullet, on on each side, making the buffs meet at one end, and strike both buffs with the hammer; this will cause the end of the pulleys to strike the inside of the cone bearing and so drive it out. Take great care not to drop the lathe, but if by accident it does have a fall, test immediately for truth.