Because the balance wheel and hairspring assembly is the time keeping element of a watch, the balance wheel must be properly poised.

In the poising operation, the mass of the balance wheel is distributed equally around the axis of rotation so that the effect of the force of gravity is eliminated. Only the forces inherent in the balance and hairspring should govern the accuracy of the balance wheel movement.

Subject: Balance Wheel Poising.

Objective: To establish the Center of gravity of a Balance at the intersection of the vertical and horizontal axis or to establish equal distribution of the mass around the Balance Wheel Staff.

Practical work – 40 hours.

Related theory – 8 hours.

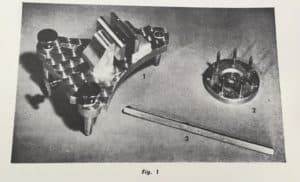

Tools Required:

1. Poising Calipers or Poising Tool.

2. Balance screw undercutter.

3. Balance screw saw.

Balance screw driver.

Slotted block.

Poising Tools And Poising Calipers

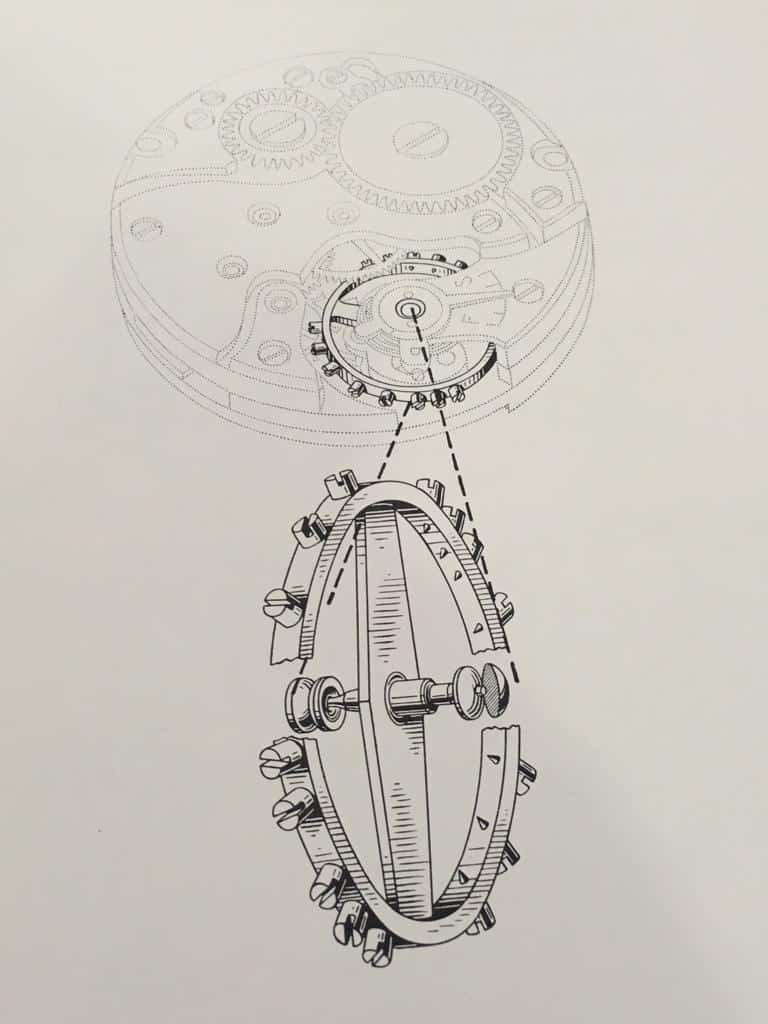

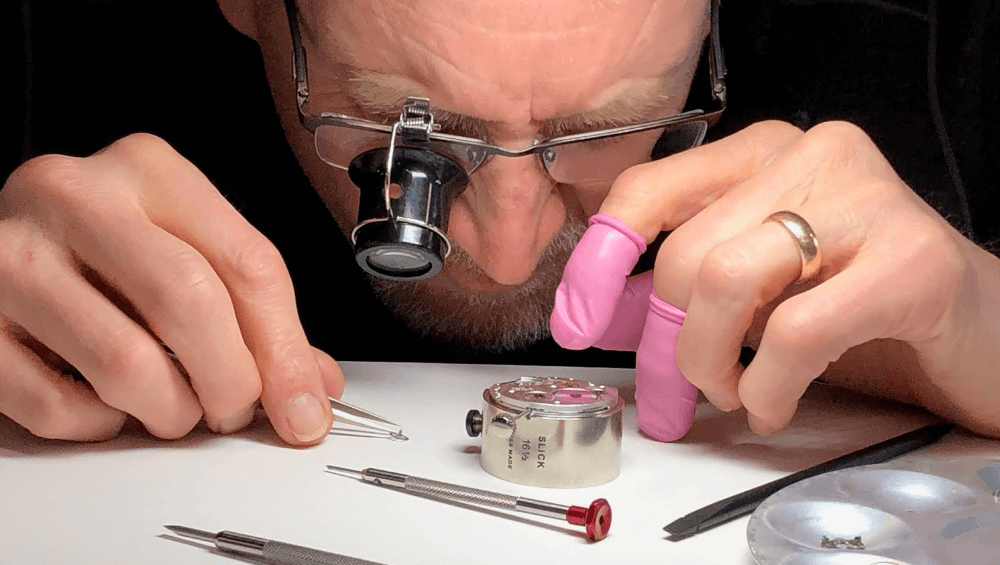

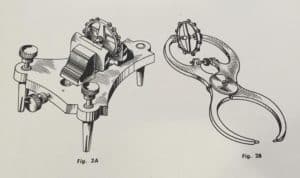

The proper use of the poising tool and poising caliper is shown in Fig. 2A and 2B. The poising tool utilizes jeweled knife edges to support the balance while the calipers are equipped with jeweled stumps that suspend the balance in such a manner that all forces acting on the balance are eliminated except the force of gravity.

Under these conditions it is reasonable to assume that any movement of the balance around its staff axis can be attributed to the force of gravity acting upon some portion of the balance to a greater extent than upon other portions. In other words, the weight of the balance is not equally distributed around the staff axis. This condition places the center of gravity away from the intersection of the two axis of the balance and the piece is said to be “out of poise”.

It would be well to recall the definition of “weight” at this time, in order to clarify this problem of poise. Weight, by definition, is merely the amount of force exerted on an object by gravity. Therefore, in the balance wheel under discussion, it is obvious that if there is a point on the rim that is heavier than other points then that point, under the pull of gravity, will be pulled downward. In short, the balance wheel will rotate until the heaviest part finally settles at the lowest point.

Once this heavy point has been determined, the whole problem resolves itself into one of redistribution of the weight in such a manner that the center of gravity will be relocated exactly at the intersection of the staff and rim axis. Particular attention is called to the phrase, “redistribution of weight”, the relationship between the weight of the balance wheel and the strength of the hairspring is an important factor controlling the accuracy of a watch.

There is a definite cooperation of physical laws in which a balance wheel that is too heavy or too light will cause a watch to lose or gain time. In view of these facts, it can be seen that it is of the utmost importance that the weight of the balance wheel is not appreciably increased or decreased during the poising operation.

The actual work involved in poising a balance wheel starts with placing the balance in the poising caliper in such a manner that only the extreme end of the pivots make contact with the strumps (see Fig. 3). In this position the calipers duplicate the conditions under which the balance must function in a watch.

It must be remembered that in actual practice a balance wheel must be poised with the roller in place. However, in this training unit the principles of balance poising will be demonstrated without the roller on the staff.

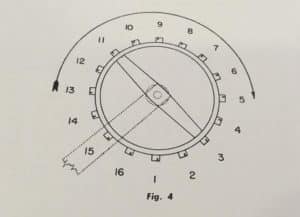

A perfectly poised balance wheel will rotate slowly as the calipers are agitated (see Fig. 4).

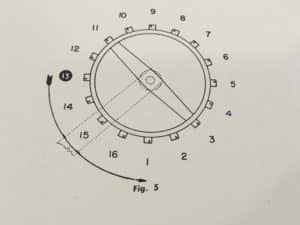

In an unpoised balance the heaviest portion of the rim will be drawn to the bottom of the wheel. In this case screw No. 13 is the indicated heavy point and will be drawn down to the lowest part of the wheel as shown by the arrow (see Fig. 5).

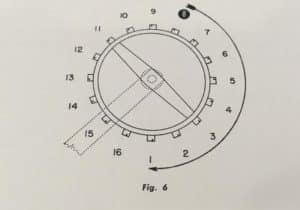

Likewise, if screw No. 8 was the heaviest it would cause the wheel to turn until this heavy point was at the bottom of the rim (see Fig. 6).

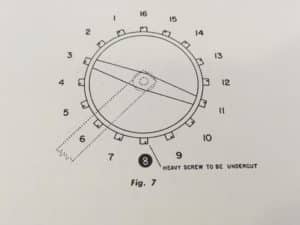

By this method it can be determined when and where the balance wheel is out of poise (see Fig. 7).

After having determined the location of the heavy screw it can be removed and replaced by the use of the balance screw remover as shown in Fig. 8A. Another method of removing the balance screw is by the use of a screw driver. After undercutting the screw it can be replaced by wedging the blade of the screw driver into the slot by the use of a block (see Fig. 8B). This wedge will support the screw so that it can be replaced into the balance wheel as shown in Fig. 8C. Care must be used in grinding the blade so that the wedge will not spread the screw slot.

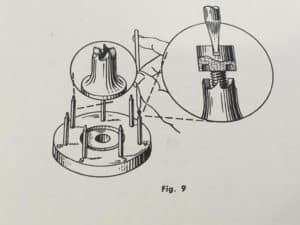

After removing the heavy screw it will be necessary to under-cut it in order to eliminate the excess weight, as shown in Fig. 9.

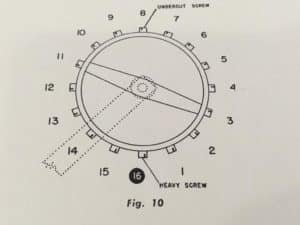

If, after replacing the under-cut screw in the same hole from which it was taken, the opposite screw shows heavy, (in this case screw No 16) the indication is that too much metal was removed in the under-cutting process on the original screw (see Fig. 10). This condition is treated as if it was the first operation of the poising procedure.

Under-cut screw No. 16 using great care not to remove too much weight with the under-cutter. Insert the screw in its proper hole and check the balance for poise.

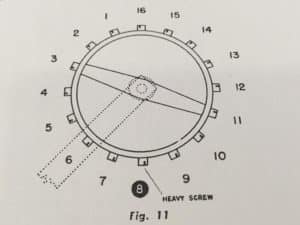

In case too much weight has again been removed it will be found that the heavy point has shifted back to the opposite side of the balance showing the rim heavy at screw No 8 (see Fig. 11). This screw must be under-cut again before the wheel can be brought into poise.

During these successive under-cutting operations, a certain amount of weight has been removed from the balance wheel. Bear in mind that any appreciable change in the overall weight of the balance will affect the rate of the watch, it might be well to consider this rate problem before attempting further under-cutting of the balance screws.

An indication of the change in the rate of the watch caused by the preceding under-cutting can be had by comparing the weight of the chips removed from the screws with the weight of a 10AK, 1 minute timing washer.

A pair of these washers added to a 10AK balance wheel will cause the watch to run one minute slow in twenty four hours. Likewise, if the weight removed from a balance during the poising operation approximates the weight of one of these timing washers, the rate of the watch will be increased about thirty seconds per twenty-four hours.

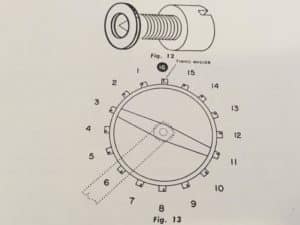

With this in mind, it is well to be constantly aware of the amount of weight being removed while poising a balance when it is apparent that a sizeable reduction in weight must be made at a point, the overall weight of the balance could be maintained by adding a timing washer to the light side and then proceed with the poising (Fig. 12 and 13).

If considerable weight has been removed from a monometalic balance the former weight may be restored by the addition of a pair of timing washers to any two opposite screws.

In the case of a bi-metallic balance wheel, temperature compensation would be less affected by adding the timing washers to the pair of screws nearest the end of the balance arm.

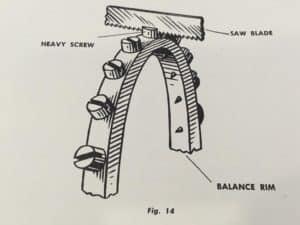

When it is determined that a wheel is very nearly in poise, a balance screw saw may be used to finish the operation (see Fig. 14).

Insert the saw in the slot of the heavy screw and carefully remove the necessary amount of metal.

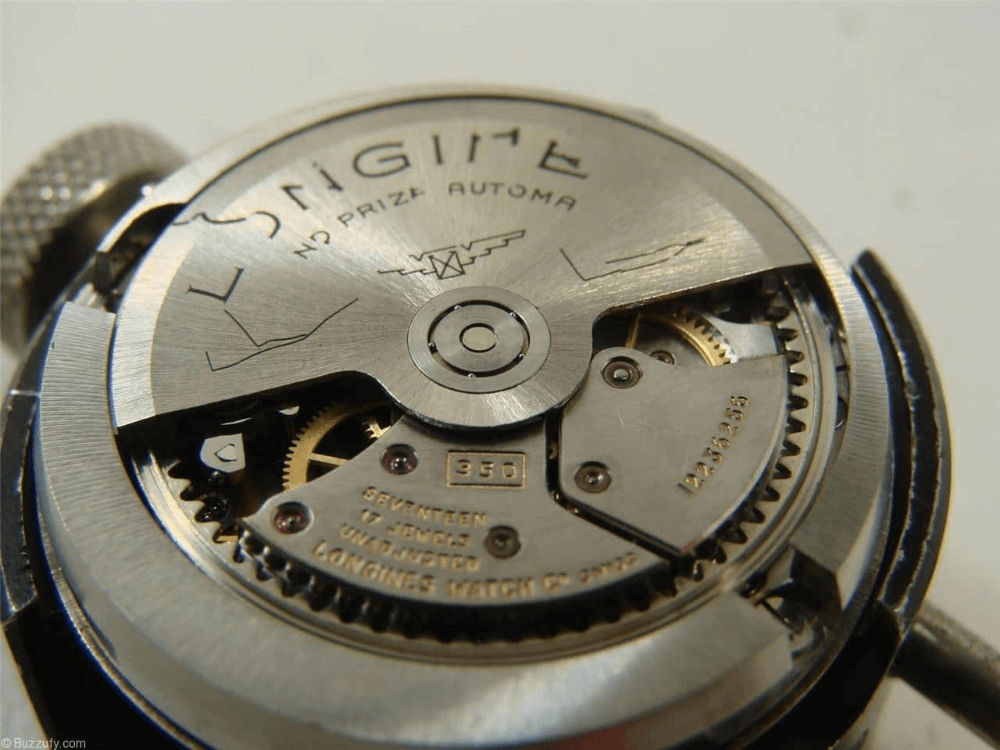

Some balance wheels are equipped with two or four meantime screws. When two screws are used they are usually located at the ends of the arm. When 4 screws are used the extra pair are located 90º from these screws. It should be remembered that meantime screws are never undercut during the poising operation.

These screws are used in the timing operation to establish the proper rate of vibration of the balance wheel. They are usually of a different color than the balance screws and slightly different in size.Before starting to poise a wheel equipped with meantime screws it is well to adjust these screws so that an even amount of thread is visible on either side of the rim. This permits a greater range of adjustment during the timing operation.

Following is another problem that may manifest itself during the poising operation.

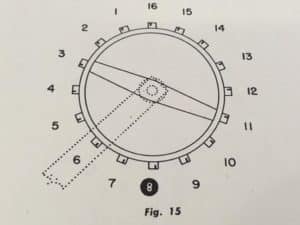

At the start of the operation a certain screw appears to be heavy, in this case, screw No. 8 (Fig. 15). This screw is carefully undercut and returned to its proper hole.

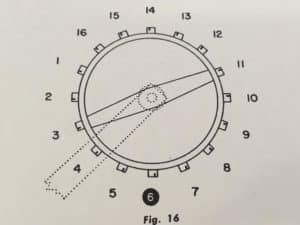

Upon testing for poise, it is found that the heavy point has shifted to another screw, No. 6, on the same side of the rim (Fig. 16). This condition is brought about by unequal distribution of weight at two or more points within the balance wheel.

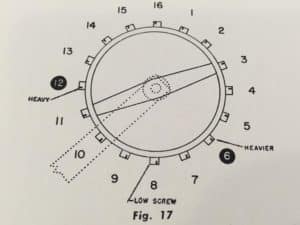

Suppose for example that screw No. 12 was slightly heavy and that screw No. 6 was even heavier.

When tested for poise this balance would settle somewhere in between these two screws (see Fig. 17).

Let’s say, for convenience, that screw No. 8 is low. According to the rules governing poising, number 8 screw is under-cut and the wheel again tested for poise.

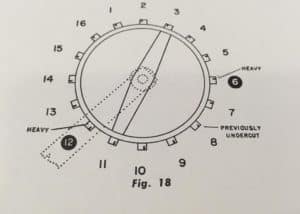

It is entirely possible that under these conditions screw No. 10 will now show heavy (see Fig. 18). This shifting of the heavy point within a certain segment of the balance rim can continue through several under-cuttings. Each successive heavy screw should be under-cut until the wheel is poised. However, if, after any one of these undercutting operations the heavy point shifts to the opposite side of the balance, it is a clear indication that too much weight was removed by the last under-cut. In any event the successive heavy screws are under-cut until the balance is in poise.

With the wheel now poised, it will be necessary to bring its weight back to the original amount, so that the rate of the watch will not have been affected by the poising.

To accomplish this, timing washers must be added as explained before.

The wheel must be checked for poise after the addition of these timing washers in order to detect any unpoised condition due to any variation in the weight of the washers.