- Balance wheel with hair spring

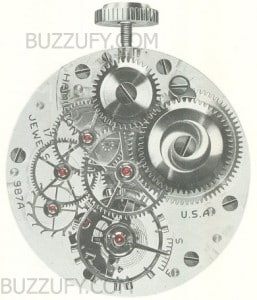

A watch is a small sturdy machine for telling time, operated by a coiled-spring motor and controlled by the oscillations of another fine spring-the hairspring-as it pulls and is pushed by the balance wheel. The coiled mainspring unwinds, turning the barrel in which it is house, once in 8 hours. The barrel is geared through a transmission train of gears, each of which, because of the ratios between gears, turns faster than the gear which precedes it. The center wheel, turned by the mainspring barrel, revolves on in one hour, This wheel turns the third wheel once in 7 ½ minutes. A simple calculation will show that both sets of wheels have a gear ratio of 8:1. The ratio between the third and fourth wheel differs. It is 7½:1, turning the fourth wheel once in one minute. The seconds hand fits on the shaft of this fourth wheel.

The fourth wheel is geared to the escape wheel with its boot-shaped teeth. The escape wheel turns once in 6 seconds. Watches with sweep second hands have an additional gear mechanism.

- Action of escape wheel, pallet and balance wheel (two positions)

The escapement is the device through which the back-and-forth motion of the balance wheel controls the continuous rotating movement of the transmission train. Key to this is the rocking escape lever that permits only one of the 15 teeth on the escape wheel to move by at a time. As a tooth moves by one pallet jewel the other pallet jewel locks another tooth. When the balance wheel swings back in the opposite direction, it releases the escape lever to permit another tooth to move by. At the same time, the movement of the escape wheel transmits enough energy to the balance wheel to keep this wheel in motion.

- Types of jewels (greatly enlarged)

Types jewels of watches (usually synthetic rubies) provide smooth, hard surfaces against which axles can turn or other movements take place with a minimum of friction and wear. The jewels are small but are precisely made. From 7 to 23 jewels are usually used in a modern watch, but the number of jewels alone does not make a watch a better timekeeper. A fine watch usually has more jewels, but it is also fine because it is made better and adjusted and tested more carefully before it is sold.

This is the double jewelling use for the balance wheel, shown at the extreme left of the chart. This is the only part of the watch that moves with considerable speed. It is also most finely balanced part of the watch mechanism. Both a hole jewel and an almost flat jewel called the endstone are used at both ends of the balance wheel staff. These hold the staff true in any position.

This is a typical hole jewel, those used in the train and indicated in the top center diagram. These are the jewels that are eliminated in the cheaper watches. If they are not of fine quality and polished to perfection, the watch is better without them. When properly polished and fitted, they not only contribute to the accuracy of a fine watch but they also reduce wear, thereby prolonging its life.

This is one of the pallet stones shown at the extreme left of the chart, They are very important jewels. Each one is struck by a tooth of the escape wheel 78,840,000 times in a year, billions of times during the life of a watch, and the slightest wear or inaccuracy would effect the accuracy of the timekeeping.

This is the roller jewel that is a part of the balance wheel assembly. Since this jewel fits inside the fork of the pallet and causes the pallet to move back and forth on its fixed axis, the whole driving power of the watch is being continually transmitted through this one tiny jewel. It must be perfectly polished and fitted and be able to resist wear.

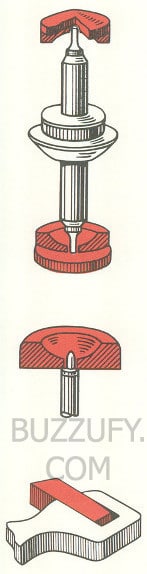

- Gearing of hands drive

A simple but extremely accurate gear mechanism allows the shaft of the center wheel which turns the minute hand through one revolution in one hour by direct drive, also to turn the hour hand one revolution in twelve hours through indirect drive.

The minute hand is tightly pressed onto the cannon pinion which is securely fitted to the shaft, so they al revolve together as a solid unit.

The cannon pinion drives the minute wheel, and the pinion of the minute wheel drives the hour wheel, the combined ratio of the gearing being twelve to one. The hour wheel is freely mounted on its own rate of speed.

The hour wheel has a tubular extension on the end of which the hour hand is tightly attached.

All the wheels of the train are turned by the energy of the mainspring, but without control they have no value in telling time. The control is supplied by the balance wheel and hairspring. The balance wheel swings back and forth 300 times a minute. At each swing it receives a slight push from the escape lever which connects the escape and the balance wheels. Because of the construction of the lever, only one tooth of the escape wheel goes by at a time. The escape wheel is then stopped till the next swing of the balance wheel permits another short movement. Thus the movement of the balance wheel holds back all the other wheels, permitting them to turn at a uniform rate. This makes timekeeping possible. The minute hand fits on the shaft of the center wheel and the second hand fits on the shaft of the fourth wheel. Another set of gears connected to the center wheel shaft operates the hour hand.

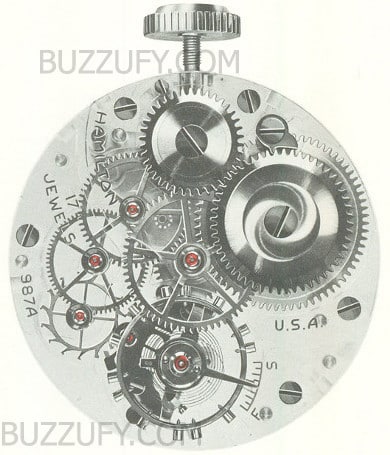

- Movement assembly

A fine watch contains from 120 to 160 parts fitted accurately together. Nesting the train and other parts is an engineering feat in itself. No space can be wasted and each wheel must be placed exactly to bring the hands to the proper place on the face. The watch represents centuries of experiment and scientific discovery. To make a fine watch requires unusual skill, fine machinery and the use of many basic resources. The perfection of machines to do many of the jobs of watch-making automatically has made possible better and less expensive watches. A fine watch, given good care and attention, will provide its owner with a lifetime of service.