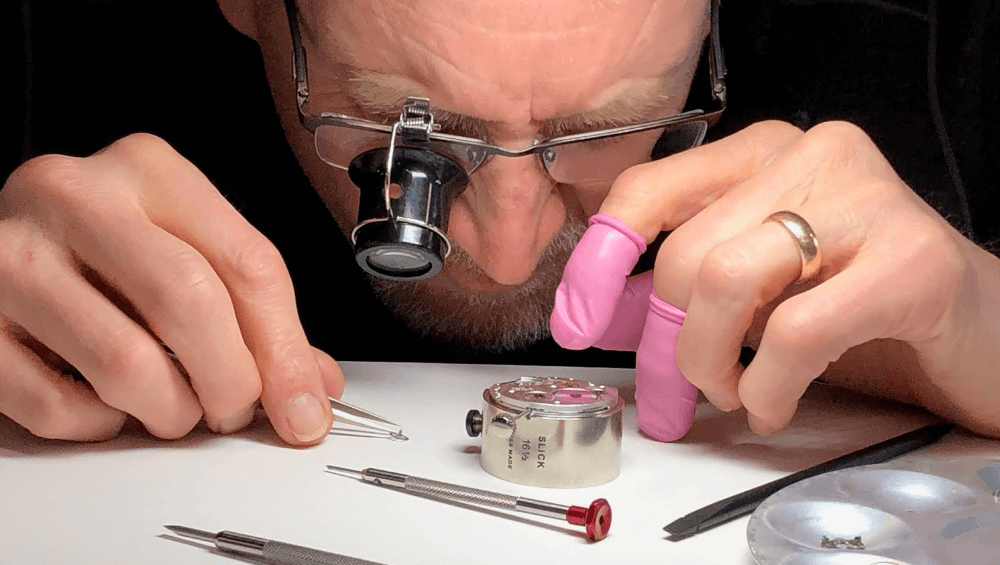

Ten years of direct research, and nearly fifty years expirience in manufacturing high-grade watches exclusively have gone into the design and construction of the Hamilton 992B Railway Special – America’s finest and most accurate railroad watch.

This is a completely new movement from winding arbor to balance wheel, and its parts are not interchangeable with those of previous 992’s.

992B is a 16 size, lever set movement with 21 friction set ruby and sapphire jewels. It is adjusted to temperature and six positions. All parts – with exception of the hairspring – are perfectly interchangeable. In addition to major technical advances (fully described in this data sheet) other changes have greatly simplifield the problems of cleaning, repairing and adjusting.

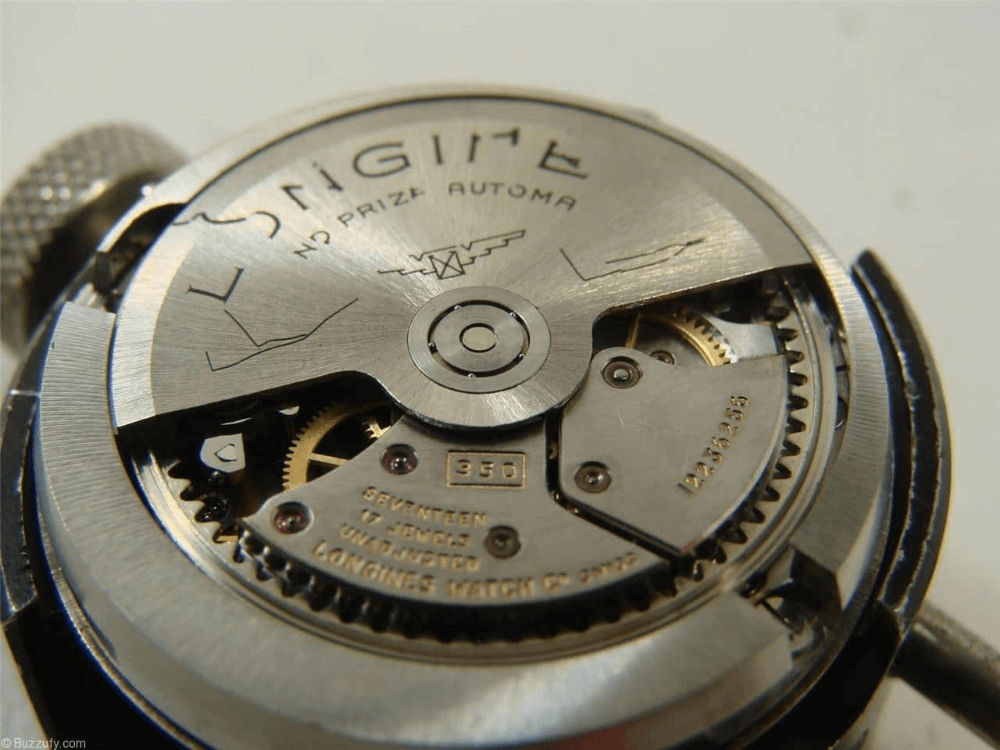

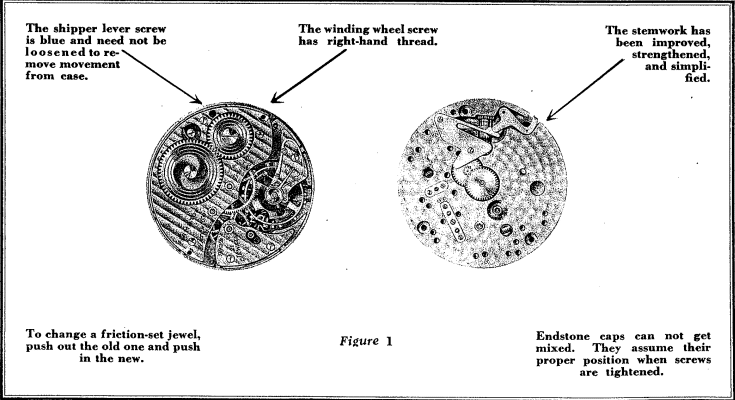

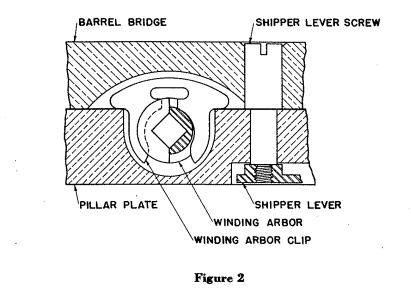

Winding and setting mechanism has been designed for increased strenght and ease of handling. The shipper lever is held in position by a screw that comes through the pillar plate from the back of the movement and is threaded into the lever. This screw is blue for indetification and need not be loosened or removed before taking the movement from the case. The winding wheel is mounted on a steel shaft and is held in position by a screw with a right-hand thread. This change in design standardizes the screws in this movement. All screws have right-hand threads. Furthermore, this winding wheel construction provides smoother action by steel bearing on nickel-silver, and prevents grease from working its way up onto the movement. The winding arbor, when in place, is surrounded by the pillar plate and is held in postion by a clip which can be removed by lifting it straight up with tweezers. This unique feature in stemwork design makes possible the removal of the barrel bridge without disturbing the winding mechanism.

Friction jeweling in this movement contributes its share to accuracy of location of train and escapement parts, and ease of handling when being assebled. To replace a broken jewel, it is only necessary to push the old one out and the new onee to the proper depth.

All the jewels have been standardized. When cleaning the movement remove the endstone caps and wash the hole jewels without removing them from the pillar plate and bridges. The hole jewels cannot get mixed or lost and the endstone caps are all of different shapes so that they can easily be returned to their original positions.

Hamilton’s new whue Elinvar hairspring is introduced for the first time in the 992B. Self-compensating for changes of temperature, protected against the effects of residual magnetism, and resistant to rust and corrosion, the new Elinvar hairspring has the hardness and elasticity of tempered steel. The chances of damaging the hairs or of disturbing fine adjustments have been reduced to a minimum. The two-piece balance staff, identified by the blue hub, can be changed without destroying trueness or poise of the balance.

To regulated the 992B, one full turn of the regulator screw will change the rate approximately fifteen seconds per day. One full turn of two meantime screws on the balance wheel will change the rate about three seconds per hour.

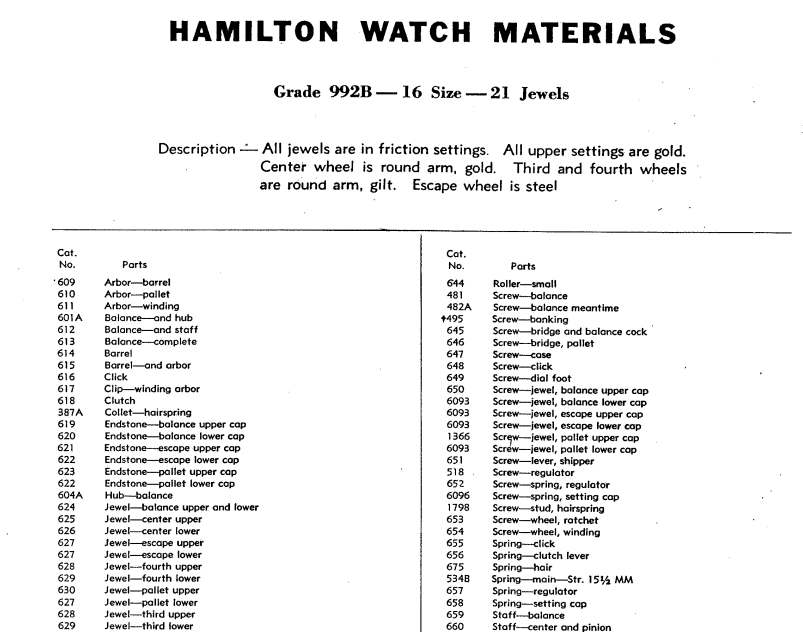

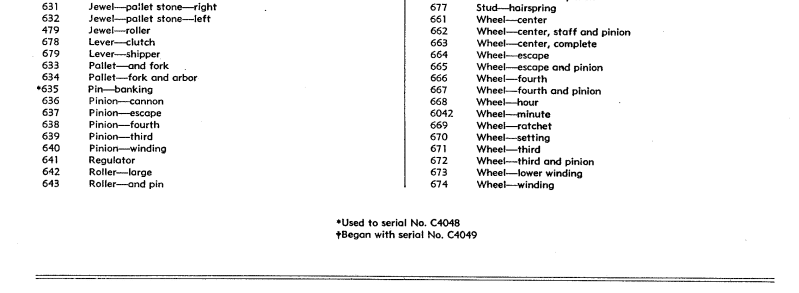

Caution – When ordering repair parts for this new 99B Railway Special, use material catalog numbers listed on the back page of this sheet. If you order parts without catalog number, be sure to specify new grade 992B.

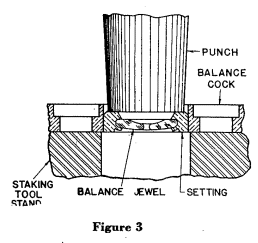

Removing train or capped jewels

Broken train or balance jewels may be removed by driving out the entire setting as illustrated in Fig.3, using a standard staking set with a flat dace punch smaller in diameter than the setting to be removed.

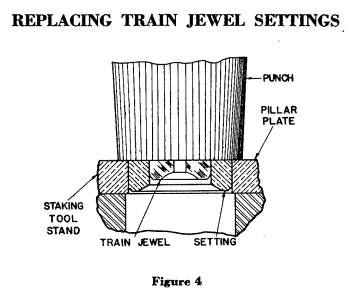

All train jewels with settings should be replaced by driving the setting into the plates or bridges from the inside as illustrated in Fig. 4. A flat face punch with a face diameter larger than the complete setting should be used first as illustrated. This will permit driving the face of the setting flush with the plate or bridge surface immediately surrounding the setting. All lower jewels are set correctly when flush. For proper end-shake the center and third upper jewels should be pushed .004” below flush, and the fourth upper should be pushed .014” below flush by using a punch smaller in diameter than the setting, as shown in Fig. 3.

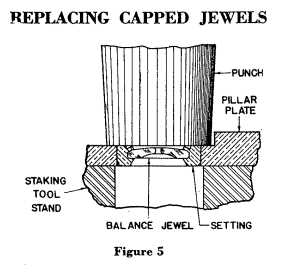

Replacing capped jewels

The escape, pallet and balance upper and lower jewels should be driven in place from the outside using a flat face punch larger in diameter than the setting and driving the jewel and setting flush with the surface of the endstone cap recess, as shown in Fig. 5. This establishes the hole jewel in its proper position so that the endstone will lay flush and parallel with the hole jewel.

Other links:

Hamilton Grade 992B watch parts