The adjustment to temperature

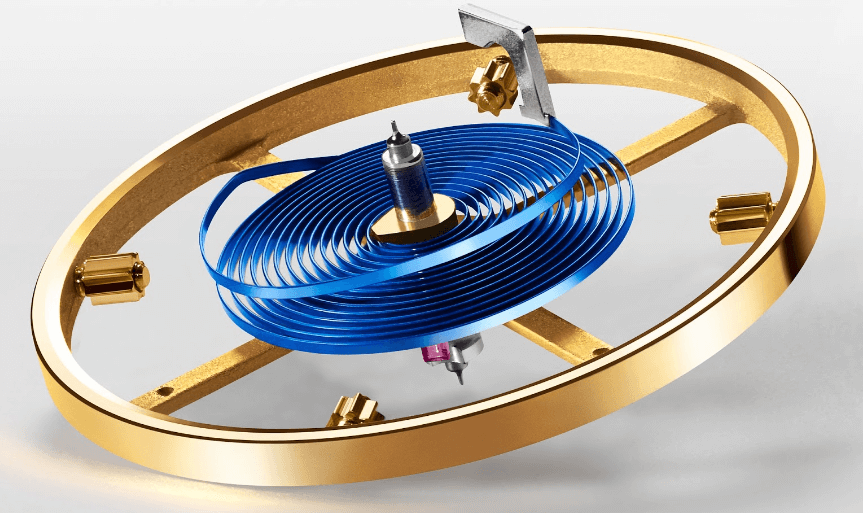

In order to attain a practical system for the temperature adjustment, the general practice has been to solder together brass and steel for the rim of the balance. The brass occupies the outer portion of the rim, consuming about three fifths of the total thickness. The rim is cut near the arms to permit the turning in and out of the loose ends, thus changing the active diameter of the wheel. This movement compensates for the changing elasticity of the balance spring during temperature changes. This type of balance is known as the compensating balance. A compensating balance made of brass and Invar (a nickle-and-steel alloy) when used in connection with a hardened steel balance spring has been and is today the most satisfactory arrangement for combating the temperature error.

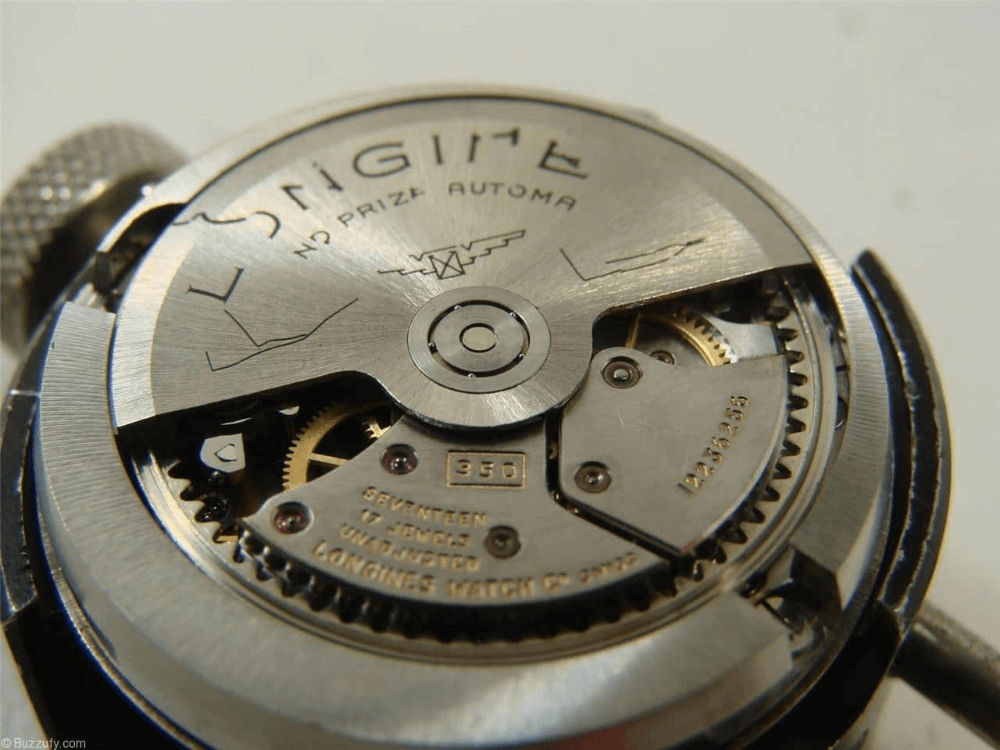

However, there is a definite trend toward the use of a plain uncut balance of a single metal and a balance spring of a nonrusting, nonmagnetizing alloy, made pricipally of a iron, nickle, chromium, and tungsten, called Elinvar. A slight temperature errors exists, but there are certain advantages that make it desirable to continue research for further improvement. This is apparently the opinion of watch factories, for new models have appeared lately with definite changes in the design on the movement as well as the balance and spring, showing a persistent effort on the part of manufacturers to improve this new type of balance assembly.

Correcting the temperature error.

Watches with pensating balances are usually adjusted to temperature between 40 degrees Fahrenheit and 95 degrees Fahrenheit.

The rules for the adjustment are as follows:

- If the watch runs slow in heat, move any even number of screws that are opposite each other an equal distance toward the loose ends of the rims.

- If the watch runs fast in heat, move any even number of screws that are opposite each other an equal distance toward the balance arms.

Experience in effecting temperature adjustment is necessary before the horologist is able to decide on the extent of the alterations. More often than otherwise, several trials are required. If the screws are moved considerable distance the poise should be examined. Temperature adjustment is practically permanent. The balance may be trued and poised many times without interfering with the temperature adjustment. However, in changing a balance spring, readjustment would be necessary.

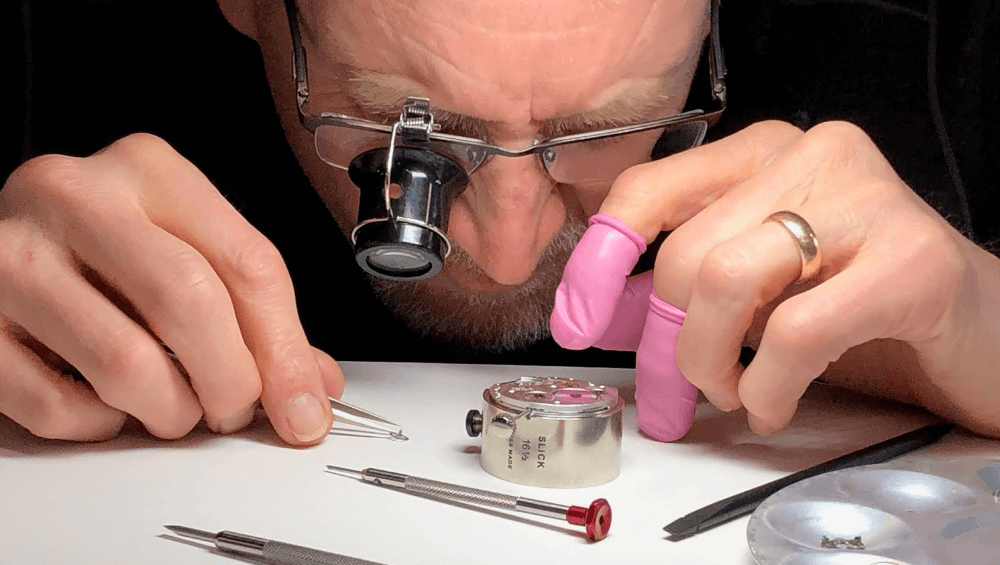

Equipment used for temperature adjustment

The equipment used for temperature adjusting is an oven and a refrigerator. An oven suitable for the purpose need be nothing more than a box fitted with an electric light bulb, a rheostat, and a thermometer. The thermometer is placed inside and in such a manner that it can be conveniently read through an opening in the box. An ordinary electric refrigerator will serve the purpose for the lower temperature.